Omni Services Industrial Supply Cover 2018

Omni Services Recognized by Industrial Supply Magazine

Omni Services was featured on the Cover of Industrial Supply Magazine – March/April 2018 Edition.

Omni Services is all about creating raving fans. A very customer driven company that keeps customers coming back.

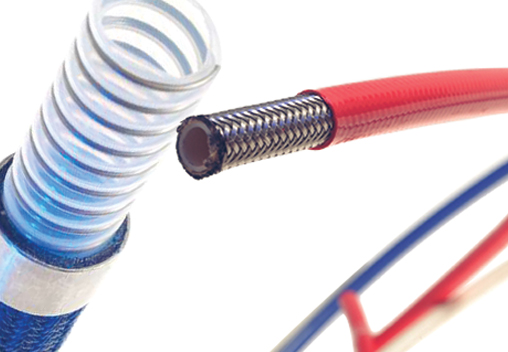

Omni’s expertise has earned the company a reputation as a fluid conveyance specialists. With sales nearing $50 million annually and 16 Locations, Omni has grown to become the leading independent distributor of hose and accessories in the Northeast, offering hydraulic hose and industrial hose products, formed tubing, instrumentation, specialty fluid transfer components and rubber.

“We’re a customer-led organization, principally speaking. That’s the simple message that is at the bedrock of why we’ve had some success over the years.” – Chuck Connors, CEO of Omni Services.

Recent Comments