Eaton Lifesense Hydraulic Hose Monitoring

Hydraulic Hose Monitoring

Hydraulic hoses are the lifelines on which heavy equipment runs. A failed hydraulic hose can put workers in danger and lead to significant downtime which can cost companies thousands of dollars. The ability to detect problems within hydraulic hoses before they fail will decrease downtime and help keep employees safe. With this in mind, Eaton has developed the LifeSense hydraulic hose condition monitoring system.

The LifeSense system is designed to alert operators when a hydraulic hose is showing signs of failing internally. This type of intelligent hydraulic hose condition monitoring system has been developed to help customers manage their hydraulic powered equipment more effectively and efficiently.

Eaton offers two options for monitoring the integrity of hydraulic hose:

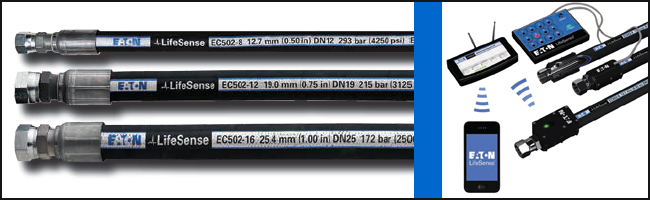

The more basic of these is the LifeSense Wired detection system. This system works by sending a direct current of 12 or 24 volts the length of the hydraulic hose. There are multiple wire cable lengths that are available for the LifeSense Wired detection system, including lengths of 10, 15, 25, 50, and 100 feet. If the LifeSense unit senses any impending failure an alert will be sent to the Hose Diagnostic Unit or HUD.

The HUD continuously monitors up to 11 hydraulic hoses by receiving real time data regarding the condition of the hydraulic hoses. In addition to the hydraulic hose condition monitoring that the LifeSense Wired system provides, it will also check the integrity of the hose fittings by means of hose fitting sensor monitor.

Eaton also has a LifeSense Wireless system that is a more advanced means of hydraulic hose condition monitoring. The LifeSense Wireless unit optimizes wireless frequency capabilities in order to monitor up to 100 hydraulic hoses and fittings. The information gathered by the wireless system is sent to a secure Eaton server, where you can monitor multiple aspects of the hydraulic system, including connection status, installation data, and trend reports.

This secure server can be accessed from a computer or a mobile device, allowing for unmatched portability. An added benefit of the LifeSense Wireless system is its ability to transmit performance data every seven hours, in addition to the continual monitoring of the hydraulic hoses.

Advantages of Hydraulic Hose Condition Monitoring System:

Implementing the Eaton LifeSense hydraulic hose condition monitoring system has multiple advantages. The detection system will increase the life of the hydraulic hoses by more than 50%, resulting in significant savings and eliminating the need to guess when a hose needs replacing.

Furthermore, Eaton LifeSense drastically reduces the chance for injury or collateral damage, by notifying workers that there is an impending failure that needs to be addressed. This early notification will allow the faulty hydraulic hose to be replaced, before rupture, which greatly reduces downtime, thus saving companies both time and money.

Recent Comments