Liquid Cooling Coupler Attachment

In the quickly evolving marketplace of data cooling there is often uncertainty around coupling attachment. We often run into the question “what is the best way to attach liquid cooling couplings?”. We’re here to help demystify coupling attachment methods available and which one is best suited for CPU liquid cooling.

Before we jump to attachment methods let’s review some of the primary concerns that should be taken into consideration. Most importantly is coupling retention, without integrity of connection a hose assembly is worthless. Size is another consideration; when working within the confines of CDUs, blades and servers there are obvious space constraints and as technology evolves everything gets both hotter and smaller.

Fluid connector manufacturers are responding but not as quickly as CPU and GPU technology is evolving. With space constraints also comes aesthetics, while not necessarily a critical consideration in tube and connector selection, it is important to many manufacturers who not only want their product to function well but also look good.

Another very important consideration is product availability within the supply chain. Manufacturing speed, quality and ease of assembly all contribute to availability. Now let’s look at liquid cooling coupler attachment methods: Clamping, crimping and push-on attachment are the three primary attachment methods that are applicable to the data cooling industry.

Clamping

Clamp style couplings have a shank designed to fit a single or double clamp to hold the coupling onto the hose or tube. One of the advantages of this attachment style is the ease of removing and reusing couplings. The clamp provides the method of connector retention for clamp style couplings. This style is often seen in refrigerant style hose and couplings.

Clamp style couplings may not lend themselves to the same consistent, repeatable assembly of every assembly due to the nature of the components (hose, connector, clamp) and the person assembling the components.

Clamps utilized in this application are typically one ear, two ear or stepless style clamps which require a special clamping tool to squeeze the ears on the clamp closed. This opens the potential for an operator to over or under clamp a coupling which would cause a premature failure. Because clamping can be imprecise pressure ratings do not apply to these hose assemblies.

Additionally clamping can add cost both as a component and in the labor it takes to assemble these components. Lastly clamping isn’t as aesthetically pleasing and can be bulkier in terms of the overall profile of the assembly causing assemblies to catch on other components or the operator during assembly.

Crimping

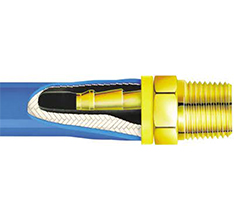

Crimp style couplings can be available in either one- or two-piece style configurations whereby the coupling shank has an outer sleeve that is crimped down over the hose pinching the hose between the shank and the sleeve offering a secure, repeatable, permeant connection.

Crimped hose and connector assemblies are lower in profile than clamped style assemblies, they are smoother, sleeker and have less tendency to get caught on other equipment or operator technicians while assembling or working on blades and servers.

Crimping is the standard in many industries but may have limited application for data cooling.

Push-On

Push-on style couplings look simple in design and can often be misidentified as clamp style connectors. There is a notable difference though, push-on style connectors have a specially designed hose barb that allows a hose or tube to be inserted but not removed.

Like a fishing hook, the barb catches on the hose so that the hose cannot be removed once assembled. This offers a fast, trustworthy, and repeatable assembly method with a reliable pressure rating. Because there is no outer sleeve or clamp the assembly has the smallest profile and isn’t a hazard to the installer. Push-on assemblies are also the best looking of the above attachment methods.

There is a place for each attachment method here depending on the media conveyed, the space constraints, overall cost and specific application. Omni Services specializes in fluid transfer solutions to meet the needs of the quickly evolving data cooling market. We would be happy to work through any questions or challenges you may have.

OMNI SERVICES

The Northeast's leading hose and accessories distributor with retail service stores located throughout Massachusetts, New Hampshire, Connecticut, Maine, New Jersey, New York, North Carolina, Delaware and Canada. With over 40 years of specializing in fluid conveyance, we continue to provide products of the highest quality and excellent service.

OUR COMPANY

Corporate Address: 12 East Worcester Street Worcester, MA 01604 USA View Map on Google

CONTACT US

Phone:1-844-365-1621

Fax: 1-508-799-2844