Instrument Valves

Valves are critical to fluid systems because they are the doors that decide what comes and goes and at what volumes and pressure; having quality instrument valves can assist you with process measurement and aid the overall success of your operation, while using the wrong one can lead to loss of production, profit or even serious safety issues for you and your team. In short, having the right valve for the application can make or break your entire fluid system; however, sourcing the right valve can be tricky.

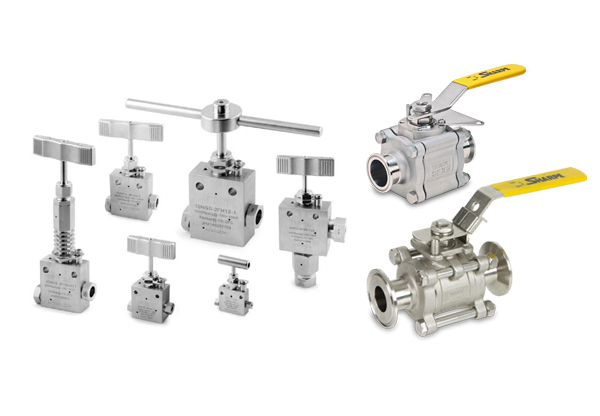

There are many different types of valves, including needle valves, encapsulated ball valves, relief valves, metering valves, safety valves, gauge valves, regulators and actuated valves, all with their own specialties and preferred applications.

At Omni Services, we recognize the importance of matching the valve to the specific application and customer, and that is why we work closely with engineering, purchasing departments and users to ensure the correct valves are selected for your system.

With over 40 years of fluid conveyance experience, Omni Services can identify the right valve for your application and craft an efficient fluid conveyance solution with unparalleled speed.

Through our partnerships with trusted suppliers that manufacture high-quality valves for every application, Omni Services will provide you with the instrument valves that you need to be successful. Connect with our Instrumentation and Process Division today and let us support your success!

The Major Functions valves perform are:

- Direction – Direct the flow path of media, with multiple circuits. (3 way ball valves)

- Regulation – Control and adjust flow rates. (Regulators, metering, needle, diaphragm, bellows valves)

- Isolation – Turn flow on or off. Connect to or isolate from a circuit (2 & 3 way ball valves, check & relief valves)

- Protection – Protect system pressures or provide filtration (check & relief valves, inline and tee filters)

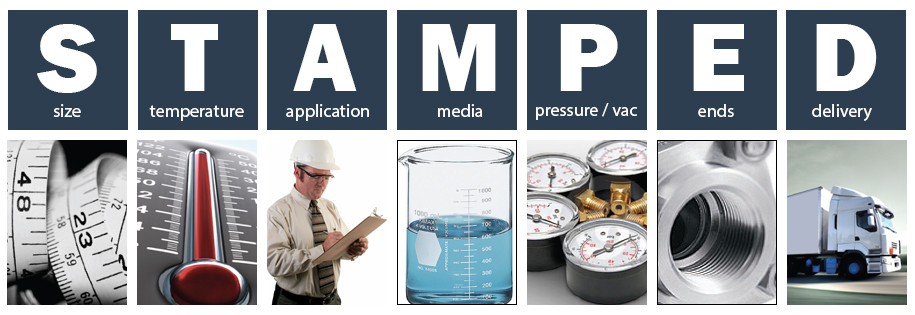

Use the STAMPED acronym when designing valves.

- Size – Connection sizes and flow rates?

- Temperature – Ambient and the conveyed media?

- Application – Agency specification approvals required?

- Media – What is being conveyed?

- Pressure/Vacuum – Maximum working pressure or vacuum to which the valve is exposed?

- End connections – What type of connection mates with the fluid system?

- Delivery/Availability – When is the valve required?

Ball Valves

Ball valves provide a quick quarter-turn on/off to stop or direct flow. These essential components are capable of handling high pressures, fluids and gases. They can also be configured for full flow or to prevent reverse flow among many other options.

Needle Valves

Needle valves are used for flow control in front of sensitive instruments, slowing sudden surges of flow. Most needle valves can shut off flow.

Check Valves

Check valves are designed for uni-directional flow control of fluids and gases in industries such as chemical processing, oil and gas production and transmission, pharmaceutical, pulp and paper, power and utilities.

Relief Valves

Relief valves are responsible for maintaining and controlling a system’s pressure levels and are often used in applications involving hydraulic fluids or compressed air. Relief valves are slightly different from safety valves, in that relief valves manage a system’s constant pressure, while safety valves are fail-safes designed to immediately vent all pressure in the event of an emergency.

Metering Valves

Metering valves offer precise flow rate control due to their life load packing and precision threads. Most metering valves do not close or shut off flow.

Butterfly Valves

Like ball valves, butterfly valves offer a quick quarter turn to open and close but are lighter weight and have a smaller profile. Butterfly valves can be manufactured in single, double and triple offset configurations depending on the media and pressures the equipment is handling.

OMNI SERVICES

The Northeast's leading hose and accessories distributor with retail service stores located throughout Massachusetts, New Hampshire, Connecticut, Maine, New Jersey, New York, North Carolina, Delaware and Canada. With over 40 years of specializing in fluid conveyance, we continue to provide products of the highest quality and excellent service.

OUR COMPANY

Corporate Address: 12 East Worcester Street Worcester, MA 01604 USA View Map on Google

CONTACT US

Phone:1-844-365-1621

Fax: 1-508-799-2844